Stay up to date with the latest news, announcements, and articles.

Operationally, immersion shifts the dominant constraints on farm design: from fan power and hot-aisle containment to heat-exchange sizing, dielectric maintenance, and fluid handling. According to Cambridge Centre for Alternative Finance datasets and related infrastructure studies, miners who integrate immersion systems with properly sized plate heat exchangers and energy-reuse loops can materially reduce PUE (Power Usage Effectiveness) and increase effective hash-density per rack. These system effects mean that the question is no longer only “which ASIC” but “which thermal system + ASIC pairing” is optimal for a given power price and site topology.

What Is Immersion Cooling?

Immersion cooling places full or partial electronic assemblies (hash boards, PSUs, control boards) into a dielectric liquid engineered to convectively remove heat directly from the ASIC packages. There are two mainstream variants used in mining: single-phase immersion (components submerged in a non-boiling dielectric, heat removed via external heat exchangers) and two-phase immersion (fluid boils on hot surfaces, carrying heat via latent heat of vaporization to condensers). Both eliminate the need for high-flow air fans and enable much more uniform thermal gradients across hash boards.

“Immersion cooling reduces thermal parasitics and allows for aggressive per-chip voltage/frequency scaling under stable junction temperatures — it’s a system-level efficiency lever.”

Immersion’s key engineering consequence is reduced temperature delta between chip junctions and ambient, which lowers leakage and enables either higher clock rates or lower supply voltages for the same hash output. That trade-space is what makes immersion attractive: you can choose higher throughput at similar power, or identical throughput at lower power, depending on your farm’s margin strategy.

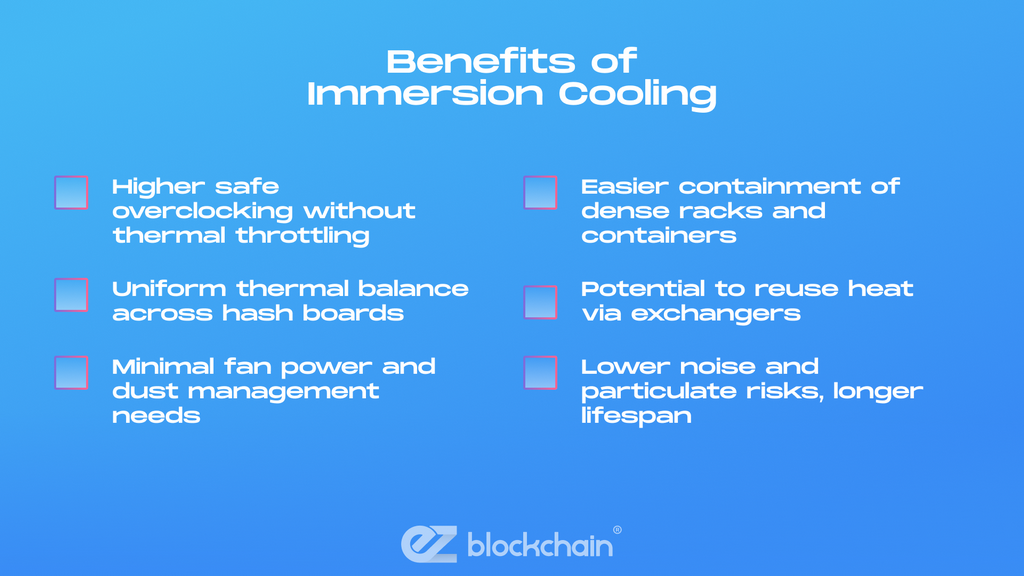

Benefits of Immersion Cooling

From an electrical-engineering and systems perspective, immersion offers several quantifiable benefits that affect both performance and total cost of ownership.

Immersion lowers steady-state silicon temperatures and reduces the need for directional airflow; this enables:

- Higher safe overclock margins on ASIC cores without thermal throttling.

- Elimination of most fan power and dust management overheads.

- Consistency of thermal conditions across hash boards, reducing hot-spot driven failures.

- Easier containment of high-density racks and containers (higher W/m³).

- Potential to capture and re-use thermal energy (e.g., heat exchangers to facility hot water).

- Reduced acoustic noise footprint, allowing closer-proximity deployment or indoor locations.

- Lower particulate ingress and oxidation risks that shorten board life in dusty environments.

Those benefits, however, come with engineering tradeoffs: dielectric fluid procurement and disposal policies, pump and heat-exchanger capital, additional site-level mechanical systems, and new maintenance disciplines (fluid quality monitoring, condensate control, and gasket integrity). For many operators the decision point is whether the delta in electricity and maintenance capex amortizes the mechanical system cost within an acceptable ROI window.

Top New Generation ASIC Miners

New-generation ASICs in 2025 are being released both as immersion-capable SKUs and as conventional air-cooled models that are commonly retrofitted into immersion tanks. The design differences matter: immersion-native ASICs may omit fan assemblies and use different PCB conformal coatings and connector layouts, whereas retrofitted air units require sealing or selective board-level modification.

“The optimal pairing is an ASIC whose thermal envelope and power delivery were specified with dielectric immersion in mind — retrofit is viable but rarely as efficient as a native design.”

New models emphasize per-die thermal telemetry, segmented power domains per hash-board, and firmware that supports finer frequency/voltage islands — all features that synergize with immersion’s thermal stability. When evaluating new ASIC SKUs for immersion, prioritize those with documented dielectric compatibility, modular hash-board replacement, and firmware hooks for per-board power capping.

Old ASIC Miners with Immersion Cooling

Older SHA-256 ASICs (S9, S17, S19 lineage and equivalents) have been widely retrofitted into immersion systems with mixed outcomes. Retrofits typically remove fan assemblies, seal air-sensitive connectors, and fit hash boards into purpose-built trays. While retrofitting reduces noise and can lower operating temperature substantially, legacy designs were not optimized for low-junction-temperature operation or per-board voltage islands, which limits the attainable efficiency gains versus newer immersion-native units [5].

| Model Family | Typical Air-Cooled Efficiency (J/TH) | Typical Retrofitted Immersion Efficiency (J/TH) | Notes |

| Antminer S9 / gen | 90–120 J/TH | 70–95 J/TH | Significant junction temp reduction; limited overclock headroom |

| Antminer S17 / S19 (older bins) | 30–50 J/TH | 25–40 J/TH | Improved stability; lifecycle extension by 6–18 months common |

| Generic 2018–2020 ASICs | 40–80 J/TH | 30–65 J/TH | Variable results depending on board age and power delivery |

| Farm-grade air units retrofit | Varies | Varies | Success depends on hash-board condition & firmware support |

In practice, operators using retrofits report a useful but bounded uplift: immersion can breathe new life into depreciated hardware by lowering failure rates and slightly improving joules-per-terahash, but the delta rarely approaches the efficiency of 2024–2025 native immersion ASIC designs.

Efficiency Comparison: Old vs New Models

Efficiency comparisons must be normalized to identical operating points (hashrate, voltage, ambient). New immersion-native ASICs prioritize lower leakage processes, on-die voltage regulation, and finer binning, producing lower J/TH at comparable hash rates relative to retrofitted legacy machines.

| Category | Nominal Hashrange (TH/s) | Air-cooled Efficiency (J/TH) | Immersion-native Efficiency (J/TH) |

| Legacy S19 / S17 class | 80–110 | 28–40 | 24–33 |

| Mid-tier legacy retrofits | 40–80 | 40–70 | 30–55 |

| New immersion-native (2024–2025) | 150–500 | N/A (not air-first) | 12–25 |

| New air-first 2025 ASICs (retrofitable) | 150–300 | 15–18 | 12–16 |

Note: the new immersion-native range reflects aggressive binning and liquid thermal envelopes. For ROI modelling, the important figure is delivered J/TH after including all auxiliary power (pumps, heat exchangers, controls) — not just ASIC core power.

Temperature, Noise, and Lifespan Analysis

Immersion dramatically reduces acoustic emissions: removing high-speed axial fans eliminates >95% of local noise sources, enabling indoor or mixed-use deployments. Temperature uniformity increases mean time between failures (MTBF) for electrolytic capacitors and solder joints; studies and field data show fewer thermal cycling events and lower board-level hotspots, which commonly are root causes of early failure.

| Metric | Air-Cooled | Immersion Retrofitted | Immersion Native |

| Typical die temp (°C) | 75–95 | 55–80 | 45–65 |

| Fan power as % of unit | 5–12% | 0–2% | 0% |

| Acoustic level (dB) @1m | 70–90 dB | 20–40 dB (tank noise) | 10–30 dB |

| Expected lifespan delta | Baseline | +6–24 months | +12–36 months (depending on fluid mgmt) |

Lifespan gains depend materially on maintenance discipline: fluid contaminants, corrosion, and dielectric breakdown are avoidable with fluid sampling, filtration, and scheduled replacement intervals.

Cost Considerations: Purchase and Maintenance

Capex for immersion includes tanks, dielectric fluid inventory, pumps, heat exchangers, and integration engineering. For large deployments, mechanical system amortization can be 8–24 months depending on scale and energy price. However, immersion reduces rack footprint and fan-related auxiliary electricity, which can materially lower operational costs per TH.

Measured studies and industry surveys indicate that immersion system TCO begins to be advantageous at scale thresholds (generally >100–200 kW per site), where infrastructure amortization spreads across many units. Cambridge and related academic sources highlight that system-level PUE improvements and higher rack density are where value accrues.

Performance Benchmarks and ROI

Performance benchmarks must include full site accounting: ASIC power, pump and heat-exchanger parasitics, facility PUE, and downtime. Field benchmarks show that immersion can increase usable hash-density per container by 1.5–2× relative to air-cooled containers, assuming proper heat rejection. ROI improvements are therefore a function of both higher effective hash per floor area and lower kWh overhead for fans and air handling.

Academic and industry reports demonstrate that, in locations with moderate power prices and good heat recovery options, immersion farms can realize payback improvements on hardware investments of 6–18% in NPV terms over air-cooled equivalents — again, highly dependent on local energy price, capex amortization schedule, and fluid lifecycle management.

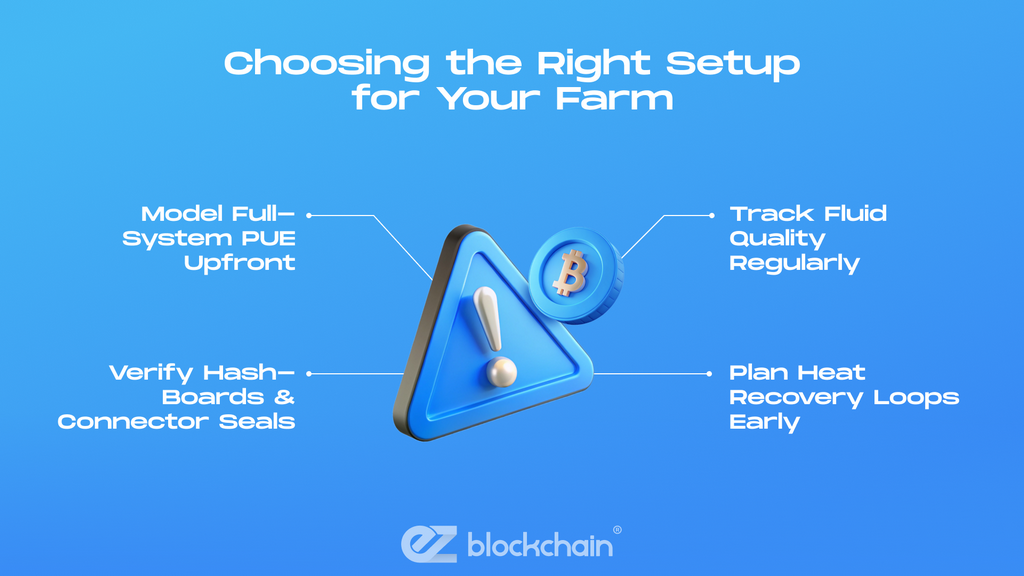

Choosing the Right Setup for Your Farm

Selecting between retrofitting old ASICs and investing in new immersion-native units requires a decision matrix that balances CAPEX amortization, energy price per kWh, site scale, and service cadence. For small farms or hobbyists, compact single-phase immersion kits may reduce noise and maintenance, but the capital outlay rarely pays off unless power is costly or collectors reuse heat. For medium to large farms, immersion native designs provide the best long-term margin if you can manage fluid logistics and heat rejection.

Short Tips:

- Model full-system PUE (including pumps and HX) before committing.

- If retrofitting, insist on hash-board test logs and connector sealing procedures.

- Build fluid quality monitoring into your maintenance schedule.

- Design heat recovery loops early — they’re the primary lever for capex justification.

If you want, EZBlockchain can run a site-specific techno-economic model (CAPEX/OPEX + fluid lifecycle + heat-recovery) to identify break-even thresholds for retrofit vs new-build immersion cooling. Reach out and we’ll build a bespoke case for your site.

Fill out a form and our bitcoin mining expert will contact you.

FREE CONSULTATIONchoose

a miner

profit and

understand data?

business remotely

with EZ Blockchain?

Fill out a form and our bitcoin mining expert will contact you.